Established in the year 1975, we, at Alliance Engineering Company, view ourselves as a vital link in the supply chain that sustains the huge global upswing in the manufacturing sector.

We manufacture and supply all types of flanges (forged as well as plate) & other machined components to customers from around the world.

Flange is a very versatile product; we cater our services to number of industrial sectors namely.

- Boiler & pressure vessels applications

- Steam applications

- Pumps & Turbines

- Oil & Gas

- Fertilizers

- Dairies & distilleries

- Steam applications

- Material handling Equipments

- Power (Thermal & nuclear)

- General Engineering

We work with a very clear focus—Complete Customer Satisfaction. We strive continuously not to simply respond to customer requirements but to anticipate them and prepare ourselves to be the most preferred source to fulfill those requirements.

Long lasting and growing relations with our customers speak for themselves of the trust and confidence that we have earned.

After over 35 years of experience in the industry, we know, Quality Never Happens as an Accident, it’s a Result of Systematic, Dedicated and Intelligent Efforts.

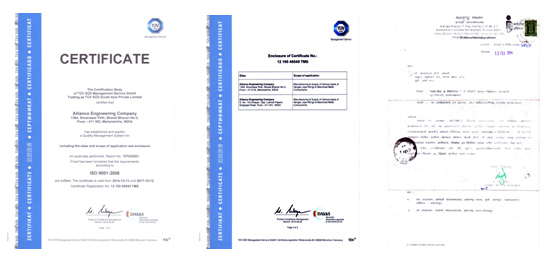

Awards and Certifications received

Our Clients:

Thermax Limited

K. S. B. Pumps Limited

Forbes Marshall Ltd

DOMESTIC

WAM India

Kirloskar Ebara Pumps

Dee Development

INTERNATIONAL

- Our products have passed the most stringent quality standards & we are proud to have customers around the globe

- We can provide our international customer list in response to serious enquiries only. If you wish to learn more about our specific customers,

-please contact us

We continue to explore new markets globally while, satisfying our current customer base

SEND ENQUIRY